Anúncios

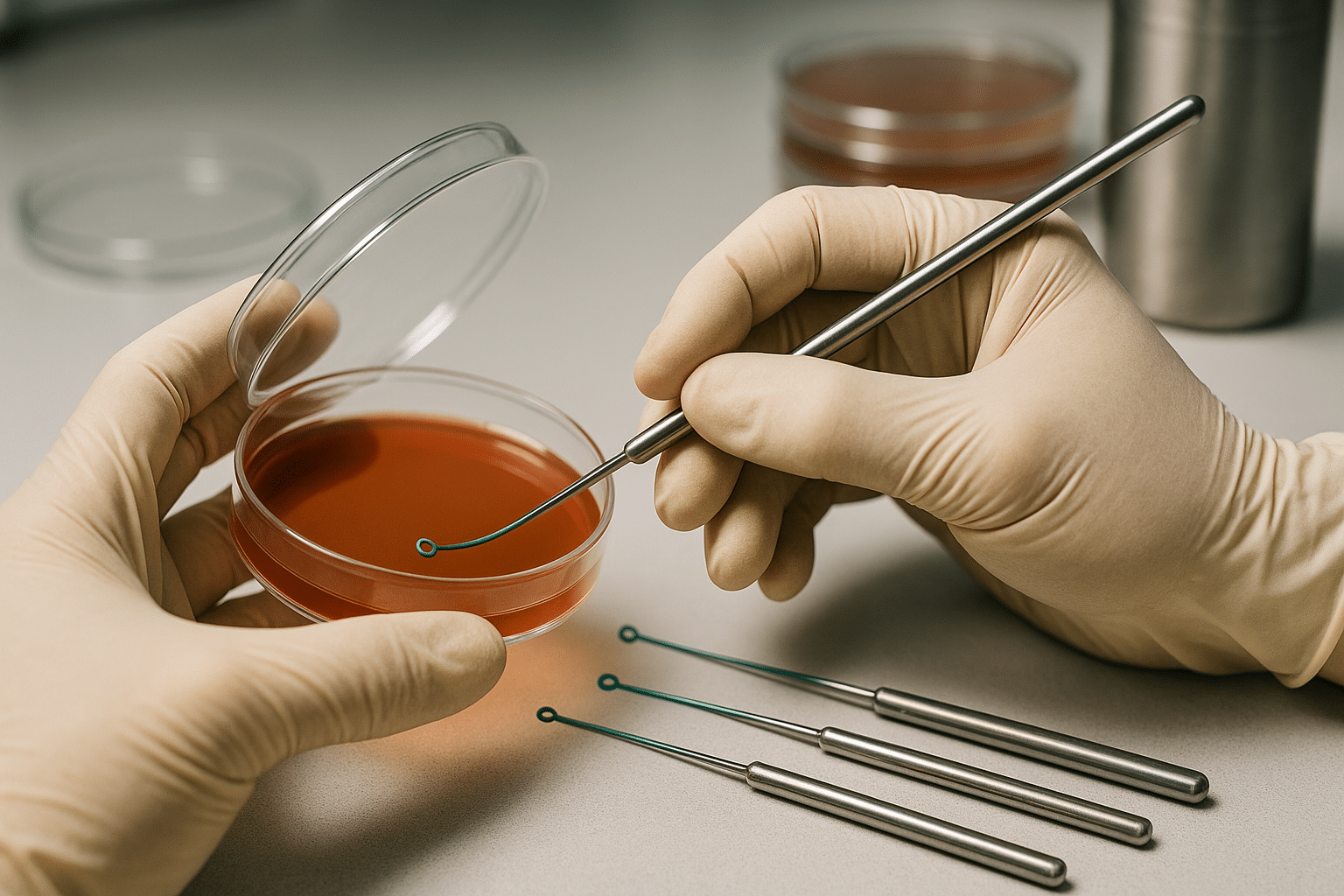

Precision in microbiology begins with the right tools, and custom inoculation loops have revolutionized laboratory techniques by delivering consistent, reproducible results every time.

🔬 The Evolution of Inoculation Loops in Modern Microbiology

The humble inoculation loop has been a staple in microbiology laboratories for over a century. Originally crafted from nichrome or platinum wire, these simple tools have undergone remarkable transformations to meet the demanding requirements of contemporary laboratory environments. Today’s custom inoculation loops represent the pinnacle of precision engineering, combining materials science with ergonomic design to create instruments that laboratory professionals can rely upon for critical work.

Anúncios

Traditional reusable loops served laboratories well for decades, but they presented significant challenges. The need for sterilization between uses created workflow bottlenecks, while inconsistent heating techniques led to variable loop sizes and potential cross-contamination. The introduction of disposable plastic loops addressed some concerns, but many researchers found them lacking in durability and precision for specialized applications.

Custom inoculation loops emerged as the solution to these longstanding problems, offering laboratories the ability to specify exact dimensions, materials, and features tailored to their unique protocols. This customization has transformed routine procedures into precision operations, enabling researchers to achieve levels of accuracy that were previously impossible.

Understanding the Anatomy of a Perfect Inoculation Loop

A well-designed custom inoculation loop consists of several critical components, each engineered to contribute to overall performance. The handle provides the foundation for control and comfort during extended laboratory sessions. Modern custom handles incorporate ergonomic principles, with textured grips that prevent slippage even when wearing gloves, and balanced weight distribution that reduces hand fatigue.

Anúncios

The shaft connects the handle to the working end, and its length, diameter, and flexibility must be precisely calibrated for specific applications. Longer shafts provide reach into deep vessels, while shorter configurations offer greater control for detailed work. The material selection for the shaft impacts both durability and sterilization options, with medical-grade stainless steel and specialized polymers being popular choices.

The loop itself represents the business end of the instrument, where customization truly shines. Loop diameter can be specified to within micrometers, ensuring consistent sample volumes across thousands of transfers. The loop’s thickness affects its capacity to hold liquid samples, while the closure quality—whether completely closed or featuring a small gap—influences how samples are retained and released.

Material Science Behind Superior Performance

The materials used in custom inoculation loops directly impact their performance, longevity, and suitability for different applications. Platinum wire remains the gold standard for reusable loops requiring flame sterilization, as it resists oxidation and maintains its shape through countless heating cycles. However, platinum’s cost makes it prohibitive for many routine applications.

Nichrome alloys offer an excellent balance of durability and affordability for flame-sterilized loops. These nickel-chromium blends withstand repeated heating while maintaining loop integrity, though they eventually oxidize and require replacement. For laboratories prioritizing cost-effectiveness in high-volume operations, nichrome represents an intelligent choice.

Medical-grade stainless steel has gained popularity for custom loops, particularly in configurations designed for autoclave sterilization rather than flaming. Stainless steel loops resist corrosion, maintain their shape under stress, and can be manufactured to extremely precise specifications. Their compatibility with various sterilization methods makes them versatile tools for diverse laboratory environments.

Advanced polymer materials have revolutionized disposable loop technology. Modern plastics engineered specifically for laboratory use combine flexibility with strength, enabling manufacturers to create loops with consistent dimensions and reliable performance. These materials resist many chemicals encountered in routine microbiology work and can be produced in virtually any color for easy identification and workflow organization.

⚙️ Customization Options That Transform Laboratory Workflows

The true power of custom inoculation loops lies in their adaptability to specific laboratory needs. Loop diameter customization allows researchers to standardize sample volumes with unprecedented precision. A 1-microliter loop transfers exactly that amount with each properly executed technique, while 10-microliter loops serve quantitative plating procedures. Custom sizing eliminates the guesswork inherent in traditional “small, medium, or large” loop selections.

Handle length and design customization accommodates different vessel types and user preferences. Technicians working with tall culture tubes benefit from extended handles that provide adequate reach without awkward positioning. Conversely, those performing detailed colony isolation on petri dishes may prefer shorter handles that offer enhanced control and visibility.

Angular configurations represent another dimension of customization, particularly valuable for specialized applications. Standard loops feature the wire perpendicular to the handle, but custom angles can facilitate access to difficult-to-reach areas or enable more natural hand positions during repetitive tasks. Some laboratories specify multiple angles for different procedures, creating a complete toolkit of precision instruments.

Color Coding for Enhanced Laboratory Safety

Custom color-coding systems prevent cross-contamination and streamline laboratory protocols. Laboratories can designate specific colors for different sample types, organisms, or procedure steps, creating visual cues that reduce errors even in busy, fast-paced environments. A blue loop might be exclusively for environmental samples, while red indicates potentially pathogenic organisms requiring enhanced biosafety precautions.

This color system extends beyond simple identification. In teaching laboratories, color-coding helps students develop proper technique by making it immediately obvious when the wrong instrument is selected. In research settings, color systems can delineate different experiments or projects, preventing accidental mixing of unrelated samples.

💡 Optimizing Technique for Maximum Precision

Even the most precisely manufactured custom inoculation loop requires proper technique to deliver optimal results. The transfer process begins before the loop touches any sample. Proper sterilization—whether by flaming, autoclaving, or using a disposable loop—ensures that only the intended organisms are transferred. For flame sterilization, the entire wire should glow red, then cool sufficiently to avoid killing the sample upon contact.

Sample collection technique significantly impacts transfer accuracy. The loop should approach the sample at a slight angle, breaking the surface tension deliberately to allow liquid to fill the loop completely. Rapid movements create bubbles and incomplete filling, while too-slow approaches may cause the sample to climb the shaft through capillary action. The optimal speed comes through practice, but custom loops with properly sized diameters make achieving consistency substantially easier.

The transfer motion itself requires smooth, controlled movement. Jerky motions scatter sample droplets, creating contamination risks and reducing the amount that reaches the target medium. Custom loops with ergonomic handles facilitate smooth transfers by reducing the muscle tension needed to maintain grip, allowing users to focus on movement quality rather than simply holding the instrument.

Inoculation Patterns That Ensure Reproducible Results

Different procedures require different inoculation patterns, and custom loops can be optimized for specific techniques. The streak plate method for isolation demands a loop that glides smoothly across agar surfaces without gouging, which means selecting appropriate loop thickness and flexibility. Stiffer loops maintain consistent pressure, while more flexible designs adapt to minor surface irregularities.

Spread plate techniques benefit from loops with slightly larger diameters that can distribute samples evenly across media surfaces. The increased surface area of a custom-sized loop speeds the spreading process while maintaining the gentle touch needed to preserve agar integrity. Some researchers specify slightly flattened loops for spreading applications, maximizing contact area without increasing volume capacity.

Quantitative transfer procedures for most probable number (MPN) determinations or viable count assays demand absolute precision. Custom loops calibrated to deliver exact volumes eliminate a significant source of variability in these critical tests. When every loop in a batch transfers within 2% of the specified volume, statistical confidence in results increases dramatically.

📊 Quality Control and Validation of Custom Loops

Implementing custom inoculation loops requires robust quality control procedures to ensure they meet specifications and deliver promised precision. Dimensional verification should be performed on representative samples from each production batch. Microscopic measurement confirms loop diameters, while volume transfer tests validate capacity specifications. Laboratories serious about precision maintain records of these validations as part of their quality management systems.

Performance testing goes beyond simple measurements. Loops should be evaluated under actual working conditions, transferring typical sample types onto standard media. This functional testing reveals practical issues that dimensional analysis alone might miss, such as whether surface tension characteristics of specific samples interact unexpectedly with loop geometry.

Long-term stability testing applies primarily to reusable custom loops. Periodic re-measurement throughout the expected service life confirms that dimensions remain within acceptable tolerances. For flame-sterilized loops, this testing is particularly important, as repeated heating gradually alters metal properties. Establishing replacement schedules based on actual performance data rather than arbitrary timeframes optimizes both quality and cost-effectiveness.

Documentation Standards for Regulatory Compliance

Laboratories operating under regulatory frameworks must document their custom inoculation loop specifications, validation procedures, and change control processes. Detailed specifications should include all dimensional tolerances, material certifications, and any special manufacturing processes. This documentation proves that the laboratory understands its tools and has deliberately selected appropriate instruments for its procedures.

Change control becomes critical when modifications to custom loop specifications are considered. Any change—material substitution, dimensional adjustment, or supplier switch—should trigger a formal evaluation of potential impacts on validated methods. Proper documentation of these evaluations demonstrates scientific rigor and protects laboratories during audits or inspections.

🌟 Advanced Applications Enabled by Precision Tools

Custom inoculation loops have enabled methodological advances that were impractical with standard instruments. Microvolume plating techniques using 1-microliter or smaller loops allow researchers to work with precious or limited samples, conserving material while maintaining statistical validity. These ultra-precise transfers are only possible with loops manufactured to exacting specifications.

Multi-loop systems represent another innovation facilitated by customization. Some researchers use sets of loops with precisely graduated volumes, enabling semi-quantitative assessments without formal dilution series. A set might include 1, 2, 5, and 10-microliter loops, each color-coded for instant identification. This approach speeds screening procedures while maintaining adequate precision for decision-making.

Specialized loop geometries serve niche applications across microbiology. Rectangular loops efficiently sample biofilm surfaces, while needle-tipped designs penetrate deeply into soft agar for motility testing. These specialized forms would be unavailable without custom manufacturing capabilities, limiting researchers to adapting standard tools for purposes they were never designed to serve.

Integration with Automated Laboratory Systems

As laboratory automation advances, custom inoculation loops designed for robotic handling are emerging. These loops feature standardized mounting interfaces, precise weight distribution for automated balancing systems, and geometries optimized for machine vision recognition. The precision inherent in custom manufacturing ensures that every loop in a batch performs identically, a critical requirement for automated systems that cannot adapt to individual variations.

Economic Considerations and Return on Investment

Custom inoculation loops typically cost more per unit than mass-produced standard loops, prompting legitimate questions about economic justification. The return on investment becomes clear when considering the total cost of laboratory operations. Improved precision reduces retesting due to ambiguous results, directly cutting reagent and labor costs. When a laboratory performs thousands of transfers annually, even small improvements in reliability generate substantial savings.

Time efficiency represents another economic benefit. Custom loops designed for specific procedures enable technicians to work faster without sacrificing quality. A loop optimized for a particular vessel configuration eliminates the awkward positioning that slows transfers with standard tools. These seconds per transfer accumulate into hours of saved labor over months of operation.

Reduced contamination rates deliver perhaps the most significant economic impact. Contaminated cultures require disposal, investigation, and repetition—a cascade of costs far exceeding the price difference between standard and custom loops. If custom loops reduce contamination rates by even 1-2%, the cost savings typically justify the investment within months.

🔍 Selecting the Right Supplier for Custom Loops

Choosing a supplier for custom inoculation loops requires careful evaluation beyond simple price comparison. Manufacturing capability determines whether a supplier can actually deliver the precision you specify. Request information about quality control procedures, measurement equipment, and process controls that ensure batch-to-batch consistency.

Communication capability matters tremendously when developing custom specifications. Suppliers should ask detailed questions about your applications, challenge assumptions that might lead to suboptimal designs, and offer suggestions based on their manufacturing experience. The best supplier relationships become partnerships where both parties contribute expertise toward optimal solutions.

Delivery reliability and flexibility distinguish exceptional suppliers from merely adequate ones. Can they accommodate urgent orders? Do they maintain inventory of your custom specifications for rapid reordering? Will they reformulate if your needs change? These practical considerations often prove more important than marginal price differences.

Future Innovations in Inoculation Loop Technology

The evolution of custom inoculation loops continues as new materials, manufacturing techniques, and application demands emerge. Additive manufacturing technologies now enable creation of loop geometries impossible to produce through traditional wire-forming methods. These 3D-printed loops can incorporate internal channels, graduated markings, or integrated sensors that provide real-time feedback during transfers.

Smart loops with embedded electronics represent the cutting edge of development. Prototype loops featuring microscale sensors can measure actual transfer volumes, detect contamination, or record temperature during flame sterilization. While currently expensive, these technologies will likely become cost-effective for critical applications as manufacturing scales improve.

Sustainable materials research aims to reduce the environmental impact of disposable loops without compromising performance. Biodegradable polymers that maintain dimensional stability during use but degrade rapidly after disposal could address growing concerns about laboratory plastic waste. Custom manufacturing allows early adoption of these materials for specific applications even before they become mainstream options.

✨ Transforming Laboratory Excellence Through Precision

Mastering the art of precision in microbiology requires more than technical knowledge and careful technique. It demands tools worthy of the critical work they perform. Custom inoculation loops represent the intersection of craftsmanship, materials science, and deep understanding of laboratory needs. When laboratories invest in truly appropriate instruments rather than accepting whatever standard options exist, they elevate their entire operation.

The journey toward precision begins with recognizing that tools matter. The right custom inoculation loop becomes an extension of the researcher’s hand, enabling techniques that feel natural rather than forced. This synergy between tool and technique creates the conditions where excellence becomes routine rather than exceptional.

For laboratories committed to producing the highest quality results, custom inoculation loops are not optional accessories but essential components of professional practice. They represent a commitment to precision that distinguishes truly excellent laboratories from those merely going through motions. In the end, mastery of any art requires mastering the tools of that art, and in microbiology, few tools are more fundamental than the inoculation loop.

Heard some whispers about 18win1. Decided to give it a whirl. Site’s alright, nothing too flashy, but it gets the job done. Registration was smooth! Definitely worth checking, especially if you like simple and straightforward. Find them here: 18win1

Часто дают фрибеты и проводят интересные промо-акции

https://romeeternal.com/2025/10/27/melbet-registraciya-2025-start/