Anúncios

UV and fluorescence visualization instruments have revolutionized modern scientific analysis, offering unprecedented capabilities for detecting invisible substances and achieving remarkable precision across diverse applications.

🔬 The Science Behind UV and Fluorescence Visualization

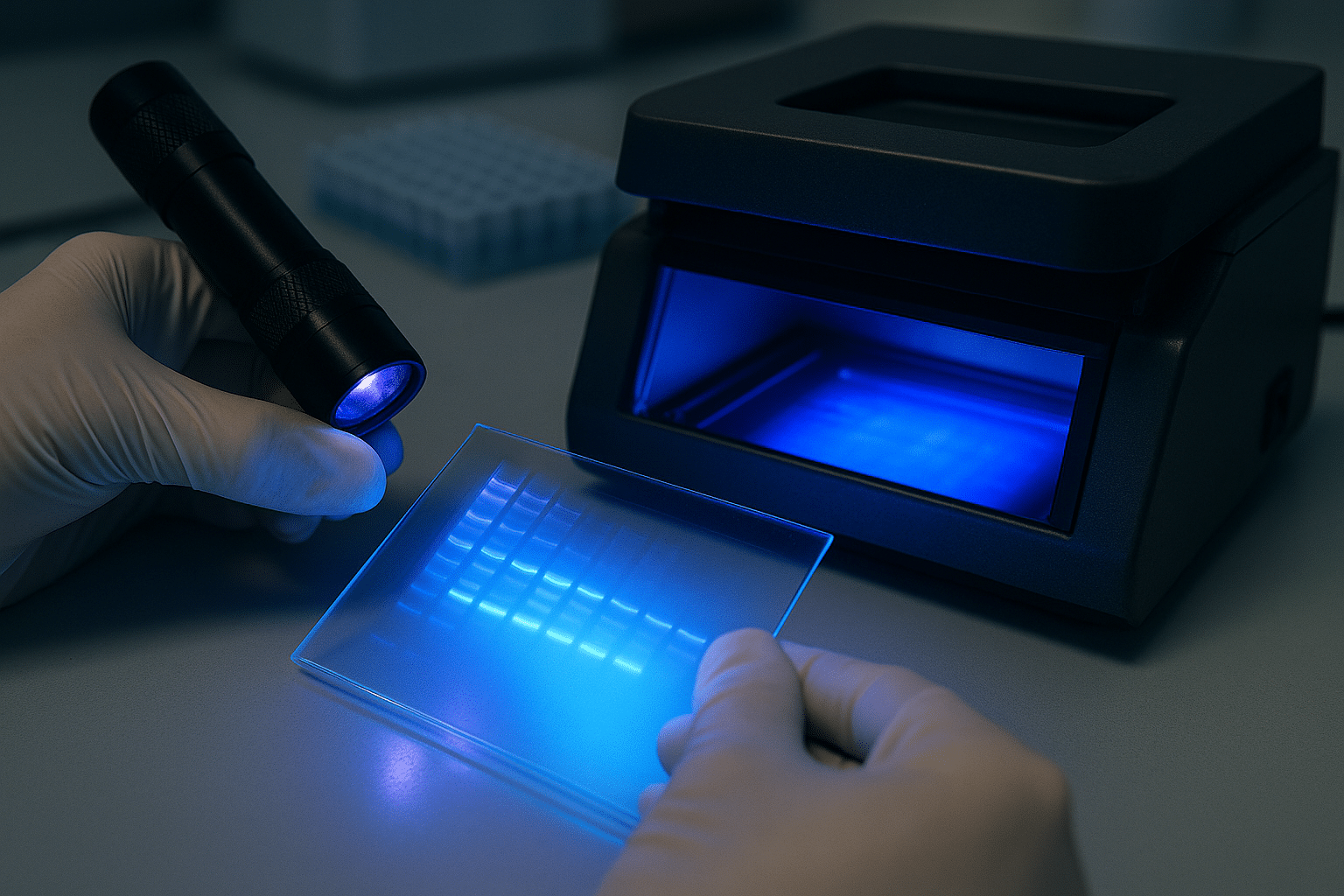

Ultraviolet light operates beyond the visible spectrum, typically ranging from 10 to 400 nanometers in wavelength. When UV light encounters certain materials, it triggers a fascinating phenomenon called fluorescence—where absorbed UV energy is re-emitted as visible light. This fundamental principle forms the backbone of countless analytical techniques used in laboratories, industrial settings, and field investigations worldwide.

Anúncios

The interaction between UV radiation and fluorescent compounds creates a powerful diagnostic tool. Different substances absorb and emit light at specific wavelengths, creating unique spectral signatures. These signatures enable scientists and technicians to identify materials with exceptional specificity, detect contaminants at incredibly low concentrations, and visualize processes that would otherwise remain completely invisible to the naked eye.

Modern fluorescence visualization instruments leverage advanced optical systems, sophisticated filters, and cutting-edge detection technologies. These components work in harmony to isolate specific wavelengths, amplify weak signals, and deliver clear, actionable results. The precision achieved through these instruments has become indispensable across numerous industries and research disciplines.

💎 Revolutionary Applications Across Industries

Forensic Science and Criminal Investigation

Law enforcement agencies worldwide have embraced UV and fluorescence visualization as essential tools for crime scene investigation. These instruments reveal evidence that standard lighting cannot detect. Bloodstains, even after cleaning attempts, fluoresce under appropriate wavelengths, allowing investigators to reconstruct crime scenes with unprecedented accuracy.

Anúncios

Bodily fluids, fingerprints enhanced with fluorescent powders, and trace evidence like fibers or hairs become immediately visible under UV illumination. Document examiners use these tools to detect alterations, reveal hidden text, and authenticate signatures. The non-destructive nature of UV examination preserves evidence integrity while maximizing information extraction.

Quality Control in Manufacturing

Manufacturing facilities leverage fluorescence visualization for rigorous quality assurance protocols. In automotive production, fluorescent dye penetrant testing reveals microscopic cracks and defects in critical components before they reach consumers. This preventive approach saves millions in warranty claims and protects brand reputation.

Electronics manufacturers employ UV inspection to verify proper coating application, detect contamination on circuit boards, and ensure solder joint integrity. The pharmaceutical industry utilizes fluorescence to confirm proper cleaning validation, detect cross-contamination, and verify packaging seal integrity—all critical factors for patient safety and regulatory compliance.

Environmental Monitoring and Safety

Environmental scientists deploy portable UV visualization instruments to detect oil spills, chemical leaks, and pollutants in water sources. Fluorescent tracers enable researchers to map groundwater flow patterns, identify contamination sources, and assess remediation effectiveness. These applications provide crucial data for environmental protection and public health.

Industrial facilities use UV detection systems to monitor for hazardous material leaks, verify proper decontamination procedures, and ensure workplace safety. The immediate visual feedback provided by fluorescence technology allows for rapid response to potential hazards, significantly reducing risk exposure for workers and surrounding communities.

🎯 Achieving Unparalleled Precision Through Advanced Technology

Spectral Selectivity and Sensitivity

Contemporary UV and fluorescence instruments offer extraordinary spectral selectivity through sophisticated filter systems and monochromators. By precisely controlling excitation and emission wavelengths, analysts can target specific fluorophores while eliminating background interference. This selectivity enables detection of target compounds even in complex matrices containing hundreds of other substances.

The sensitivity achieved by modern instruments borders on the remarkable. High-quality fluorescence spectrometers can detect concentrations in the parts-per-billion or even parts-per-trillion range. This extreme sensitivity makes fluorescence visualization invaluable for trace analysis applications where traditional analytical methods fall short.

Quantitative Analysis Capabilities

Beyond simple detection, advanced fluorescence systems provide robust quantitative analysis. By measuring fluorescence intensity and correlating it to concentration through calibration curves, scientists obtain precise measurements of analyte quantities. This quantitative capability transforms fluorescence from a qualitative screening tool into a rigorous analytical technique.

Modern instruments incorporate sophisticated software that automates data collection, performs complex calculations, and generates comprehensive reports. Statistical analysis features ensure measurement reliability, while method validation tools help laboratories maintain compliance with regulatory standards. These capabilities elevate fluorescence visualization to the level of gold-standard analytical techniques.

🏥 Medical and Biological Applications Transforming Healthcare

Diagnostic Medicine and Pathology

Fluorescence microscopy has revolutionized cellular and molecular biology research. Immunofluorescence techniques allow researchers to visualize specific proteins within cells, track cellular processes in real-time, and understand disease mechanisms at the molecular level. These insights have accelerated drug discovery and personalized medicine development.

Clinical laboratories employ fluorescence-based assays for rapid disease diagnosis. Fluorescent antibody tests detect pathogens, autoimmune markers, and cancer biomarkers with exceptional speed and accuracy. Point-of-care fluorescence devices enable bedside testing, delivering critical diagnostic information within minutes rather than hours or days.

Surgical Guidance and Tumor Visualization

Surgeons increasingly rely on fluorescence-guided surgery to achieve complete tumor removal while preserving healthy tissue. Fluorescent dyes administered before surgery accumulate preferentially in tumor cells, making them glow under specialized surgical lighting. This real-time visualization dramatically improves surgical precision and patient outcomes.

Vascular surgeons use fluorescent angiography to assess blood flow during reconstructive procedures, ensuring adequate tissue perfusion. Neurosurgeons employ fluorescence to distinguish tumor margins from critical brain structures, minimizing collateral damage. These applications demonstrate how fluorescence visualization directly translates to improved patient care and survival rates.

🔧 Selecting the Right Instrumentation for Your Needs

Key Performance Specifications

When evaluating UV and fluorescence visualization instruments, several critical specifications demand careful consideration. Wavelength range determines which fluorophores you can effectively excite and detect. Broader ranges offer greater flexibility but may compromise performance at specific wavelengths compared to specialized instruments.

Sensitivity specifications, typically expressed as signal-to-noise ratio or detection limits, indicate the instrument’s ability to detect weak fluorescence signals. Higher sensitivity enables analysis of dilute samples and detection of trace contaminants. Dynamic range—the span between minimum detectable signal and saturation—determines measurement versatility across concentration ranges.

Resolution specifications define the instrument’s ability to distinguish closely spaced spectral features. Higher spectral resolution enables more detailed characterization of fluorescent compounds and better separation of overlapping signals from multiple fluorophores in complex samples.

Portability Versus Laboratory Performance

Applications dictate whether portable or benchtop instrumentation best serves your needs. Portable UV lamps and handheld fluorescence viewers offer unmatched convenience for field investigations, manufacturing floor inspections, and on-site verification tasks. These devices sacrifice some performance capabilities for mobility and ruggedness.

Laboratory-grade spectrofluorometers provide maximum sensitivity, resolution, and analytical capabilities. These instruments excel at quantitative analysis, method development, and research applications where ultimate performance justifies the investment. Many laboratories maintain both portable screening tools and high-performance benchtop systems for comprehensive analytical capabilities.

⚡ Emerging Technologies Expanding Possibilities

Smartphone-Based Fluorescence Detection

Recent innovations have transformed smartphones into powerful fluorescence detection platforms. Attachable UV LED modules and specialized filters convert standard smartphones into portable fluorescence analyzers. Custom applications provide image processing, quantitative analysis, and data management—all in a pocket-sized package.

These smartphone-based systems democratize access to fluorescence technology, enabling applications in resource-limited settings, citizen science projects, and field research. While not matching laboratory instrument performance, smartphone fluorescence detectors deliver surprisingly capable results for screening applications and semi-quantitative analysis.

Artificial Intelligence Integration

Machine learning algorithms increasingly enhance fluorescence visualization capabilities. AI-powered image analysis automatically identifies regions of interest, classifies fluorescence patterns, and detects anomalies that might escape human observation. These capabilities accelerate analysis, reduce operator bias, and extract maximum information from fluorescence data.

Predictive algorithms trained on extensive fluorescence datasets can identify unknown compounds, predict sample characteristics, and optimize measurement parameters automatically. This intelligence augmentation extends the effective capabilities of both instruments and operators, enabling more sophisticated analyses with reduced training requirements.

📊 Best Practices for Optimal Results

Sample Preparation and Handling

Achieving reliable fluorescence measurements begins with proper sample preparation. Contaminants exhibiting autofluorescence can generate false positives or obscure target signals. Thorough cleaning of sample containers and preparation tools with UV-free solvents minimizes background fluorescence.

Sample concentration significantly impacts measurement quality. Excessively concentrated samples may exhibit inner filter effects or self-quenching, where fluorescence intensity doesn’t linearly correlate with concentration. Dilution to optimal concentrations ensures accurate quantification and prevents instrument saturation.

Temperature control matters for fluorescence measurements, as quantum yields and spectral properties vary with temperature. Thermostatically controlled cuvette holders maintain consistent conditions, improving measurement reproducibility. For field applications, allowing samples to equilibrate to ambient temperature before measurement reduces variability.

Calibration and Quality Control

Regular calibration with certified fluorescence standards ensures measurement accuracy and traceability. Wavelength calibration verifies that the instrument correctly identifies spectral features, while intensity calibration establishes quantitative accuracy. Documenting calibration results creates audit trails essential for regulatory compliance.

Quality control samples analyzed alongside unknowns verify that instrument performance remains within specifications. Control charts track measurement precision over time, revealing trends that may indicate maintenance needs before they compromise data quality. Implementing robust quality control protocols protects against costly errors and regulatory violations.

🌟 Cost-Benefit Analysis and Return on Investment

The initial investment in UV and fluorescence visualization equipment ranges from hundreds to hundreds of thousands of dollars depending on capabilities and applications. However, the return on investment often manifests rapidly through improved efficiency, enhanced quality control, and risk mitigation.

Manufacturing facilities report significant cost savings from detecting defects before products leave the factory. Early detection prevents warranty claims, recalls, and reputation damage—expenses that dwarf equipment costs. Environmental monitoring applications prevent regulatory fines and cleanup costs by enabling rapid response to contamination incidents.

Research laboratories gain competitive advantages through advanced fluorescence capabilities, securing grants, publishing high-impact studies, and attracting collaborative opportunities. The data quality improvements enabled by precision fluorescence instrumentation accelerate research timelines and increase experimental success rates.

🚀 Future Horizons in Fluorescence Technology

Ongoing developments promise even more powerful fluorescence visualization capabilities. Hyperspectral fluorescence imaging systems capture complete spectral information at every pixel, enabling simultaneous detection of multiple fluorophores with unprecedented specificity. Time-resolved fluorescence techniques distinguish fluorophores based on emission kinetics, adding another dimension for compound differentiation.

Miniaturization trends continue delivering laboratory-grade performance in increasingly compact packages. Microfluidic devices integrate sample handling, fluorescence detection, and analysis in chip-scale formats. These lab-on-a-chip systems enable rapid, automated analyses using minimal sample volumes—ideal for point-of-care diagnostics and high-throughput screening.

Quantum dot fluorophores with tunable emission wavelengths, superior brightness, and exceptional photostability are revolutionizing fluorescence applications. These engineered nanoparticles enable multiplexed detection of numerous targets simultaneously, expanding experimental possibilities in biological research and diagnostic testing.

💡 Maximizing Your Investment Through Proper Training

Even the most sophisticated fluorescence instruments deliver optimal results only when operated by knowledgeable users. Comprehensive training programs ensure personnel understand fundamental fluorescence principles, instrument capabilities and limitations, and proper operational procedures. This knowledge foundation prevents costly mistakes and maximizes data quality.

Ongoing education keeps users current with emerging techniques, new applications, and software updates. Manufacturers typically offer training resources including webinars, application notes, and technical support. Professional societies provide conferences, workshops, and certification programs that deepen expertise and facilitate knowledge exchange among practitioners.

Developing standard operating procedures tailored to your specific applications ensures consistent results across different operators and time periods. Documentation of methods, troubleshooting protocols, and maintenance schedules creates institutional knowledge that persists despite personnel changes. This systematic approach transforms fluorescence visualization from an art into a reliable, reproducible analytical technique.

✨ Embracing Precision Through Fluorescence Innovation

UV and fluorescence visualization instruments represent powerful allies in the pursuit of analytical excellence. Their ability to reveal invisible phenomena, detect trace quantities, and provide quantitative measurements with exceptional precision makes them indispensable across scientific disciplines and industrial applications. As technology continues advancing, these capabilities will only expand, opening new possibilities for discovery and quality assurance.

Organizations investing in appropriate fluorescence instrumentation, coupled with proper training and implementation of best practices, position themselves at the forefront of analytical capabilities. The glowing results achieved through these technologies deliver tangible benefits—from safer products and protected environments to breakthrough discoveries and improved healthcare outcomes. The future of precision analysis shines brightly, illuminated by the power of fluorescence visualization.